Jewels Packaging, Uncategorized, Printing, Informative Articles

What is Silk Screening?

Silk Screen Printing

As its name implies, this printing technique relies on a screen, which is a woven piece of fabric. Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh that allows ink to transfer onto the material. A roller or squeegee is moved across the screen stencil, forcing or pumping ink past the threads of the woven mesh in the open areas.

The advantage of screen printing is that the surface of the recipient does not have to be flat and that the ink can adhere to a wide range of materials, such as paper, textiles, glass, ceramics, wood, and metal.

History

Silkscreen Printing can be traced as far back as 9000 BC, when stencils were used to decorate Egyptian tombs and Greek mosaics. From 221-618 AD stencils were used in China for production of images of Buddha. Japanese artists turned screen printing into a complex art by developing an intricate process wherein a piece of silk was stretched across a frame to serve as the carrier of hand cut stencils.

Silkscreen Printing can be traced as far back as 9000 BC, when stencils were used to decorate Egyptian tombs and Greek mosaics. From 221-618 AD stencils were used in China for production of images of Buddha. Japanese artists turned screen printing into a complex art by developing an intricate process wherein a piece of silk was stretched across a frame to serve as the carrier of hand cut stencils.

Silkscreen printing found its way to the west in the 15th century. The original material used in screen printing was silk. Hence the name Silkscreen printing. Today polyester is the fabric of choice.

In the United States, screen printing took on the status of art in the 1930s when a group of artists working with the Federal Art Project experimented with the technique and subsequently formed the National Serigraphic Society. American artists began making “fine art” screen- prints and devised the term “Serigraph” to distinguish fine art from commercial screen printing. During the 1960s, Serigraphy was popular with POP artists, who were attracted to its bold areas of flat color.

The Printing process

The basic printing process is the forcing of ink through a stencil onto paper with a squeegee. This is called “pulling” Each color must be printed in the same place and in the same order for each print to resemble the original.

An original image is the first step in the process. Then the screen printer uses his knowledge of and preferences for color to develop a separate stencil for each color. Each stencil is then adhered to its own screen.

Inks are custom mixed by the artist and matched to colors of the original and desired outcome of hue and value. In my prints, the number of colors on a silkscreen print varies: usually there are at least six different colors, but there may be up to 40 colors on a single image.

The screen printer pulls ink across the printing frame, which has been placed above a sheet of paper that will hold the art work. The ink is then forced through the screen and onto the paper below. This process is repeated on all sheets of the edition, and then the stencil is destroyed.

Applications Of Screen Printing

The textile industry probably makes the largest use of the screen printing technique. Screen printing is used to print on fabrics ranging from cotton and organza to silk and polyester. These fabrics are then made into finished products. The finished products include shirts, skirts, dresses, children’s clothing and any kind of clothing made from printed the fabric. In fact many designers set up their own screen printing units since they are so cheap.

The designer then creates his or her own design and screen prints it in limited quantities for sale with his or her brand label. Screen printing is also used for upholstery, linen, curtains, drapes, cushion covers, bed sheets, bedcovers and other household and lifestyle requirements.

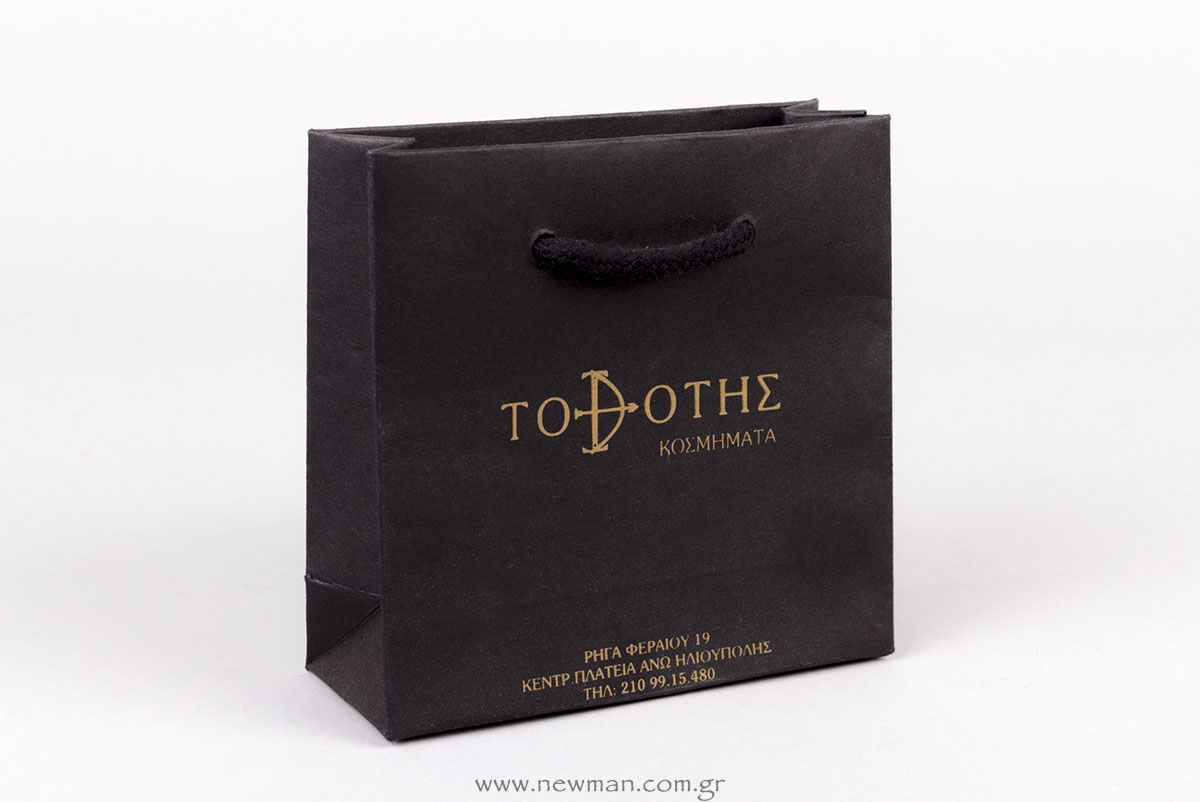

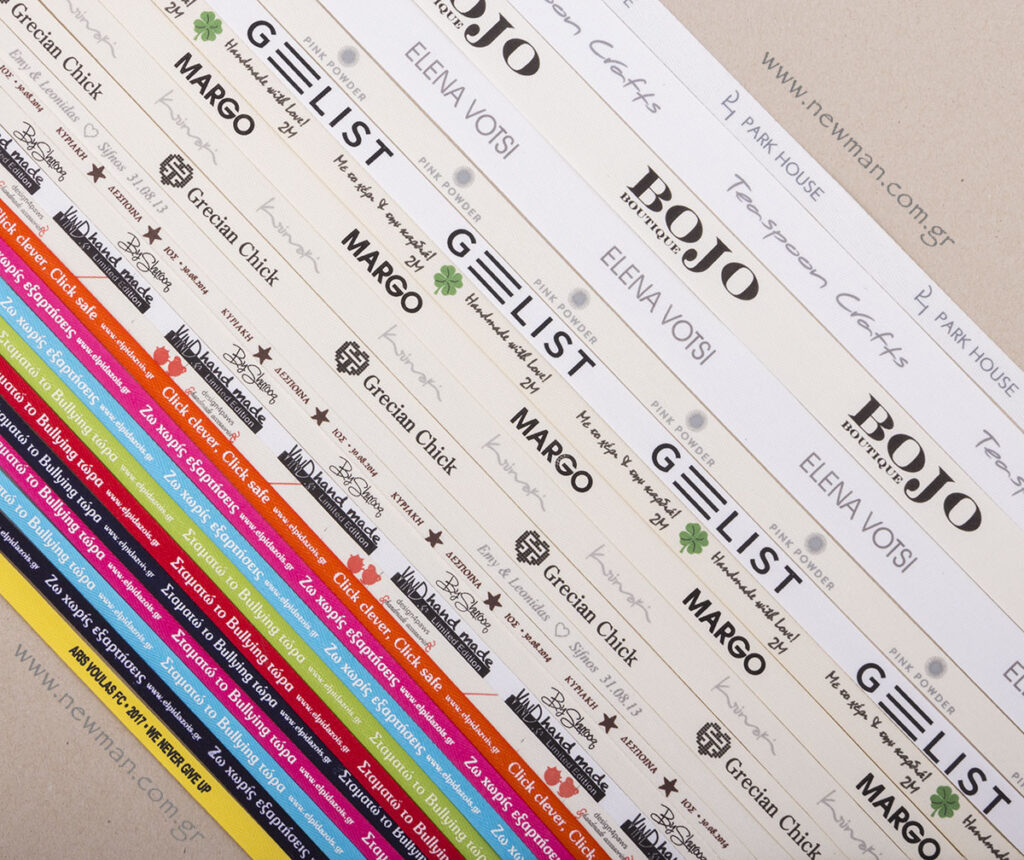

The other industry that makes extensive use of screen printing is the marketing and advertising industry. Flyers, posters, hand outs, advertisements and other point of sale or graphics products are all screen printed. Screen printing is widely used in packaging industry. Bags, ribbons, boxes, stickers and other packaging materials are printed to “carry” the brand of each business, and thus raise the awareness of each brand to potential customers. The advertising industry uses screen printing primarily because it generally requires limited edition printing. The costs of printing small quantities digitally or electronically can be very high. Hence screen printing to the rescue.

The sports industry also uses screen printing to print souvenirs and collectible items. T-shirts printed with the logos of popular teams, souvenirs like caps, sweatshirts, mouse pads, keychains, baseball bats and a host of other items are all screen printed. Thus, screen printing has innumerous applications. Everywhere you look you will find examples of screen printing. Some are overt and others will be disguised.

© 2017 Newman Co., All rights reserved.